Thank you all SO much for supporting us through our crowdfunding efforts. We raised $13,574 of our $10,000 goal in the end, our most successful crowdfunding campaign to date.

Welcome to our Spring 2021 Newsletter. This is our second in a series of newsletters that focus on a small group of subsystems. This month we focus on the Brakes + Driver Interface, Drivetrain, and Electrical subsystems.

Brakes + Driver Interface (BDI)

BDI is working to improve our new pedal and pedal tray designs. Below is a prototype we have designed completely from off the shelf components with minimum machining in order to calculate the optimal return force as the throttle pedal is pressed. We can calculate the range of linear forces exerted by the spring that will give the preferred reaction force. Once the range is determined, torsion springs capable or producing similar forces will be purchased for the actual spring return mechanism. The assembly can also be used for other experiments that require a prototype of the pedal assembly in order to test out design ideas or other potential sensors.

Drivetrain

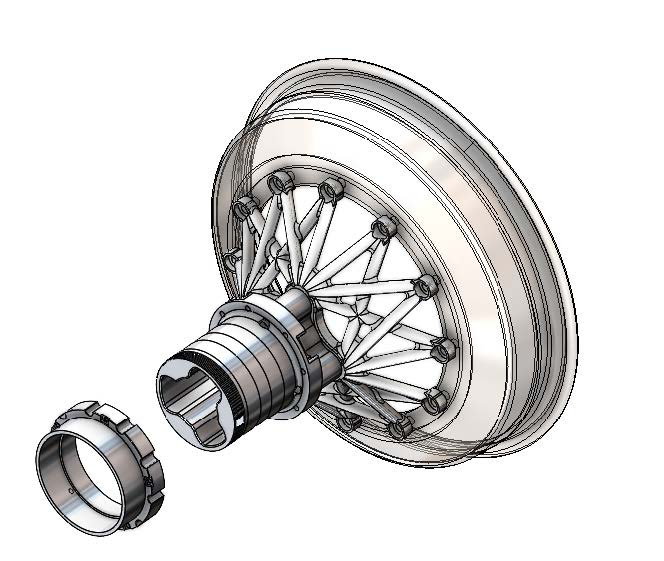

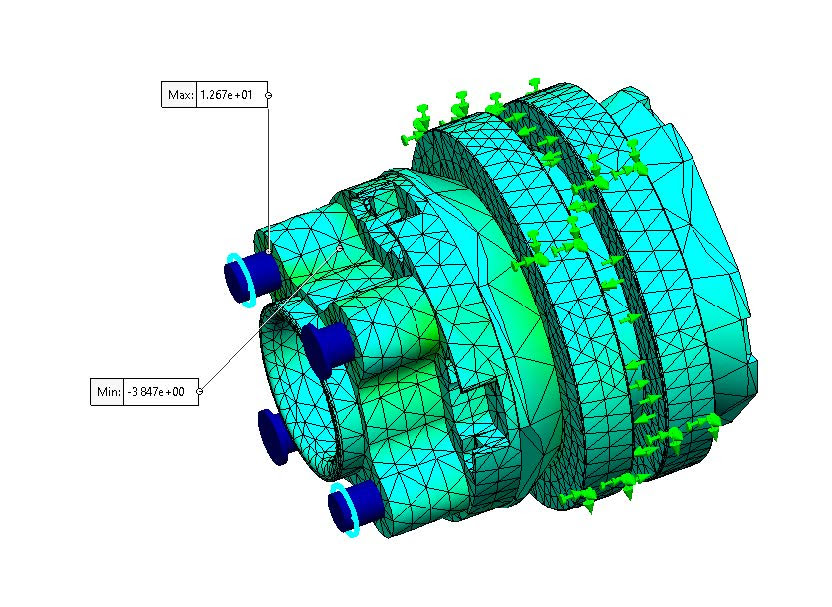

Over the past few months, Drivetrain has been working on finalizing the new wheel package design under a series of re-evaluated load cases that we hope will provide insight into the overall compliance of the system and whether or not we will see improvement in the stiffness of the wheel package. The new design reduces tolerance stack up in manufacturing, as well as distributing load more evenly and directly to the upright feature that supports the wheel.

In addition to our progress on the wheel package, we have been looking into generative design methods for optimizing the way we mount the differential to the rear bulkhead, taking into account the loads applied along the chain line, jacking tube load, and torques induced by these load cases.

Over the next few weeks, we plan to finalize designs for both the wheel package and the differential, and move into a broader assembly perspective working to evaluate new axle length and parts sourcing.

Electrical

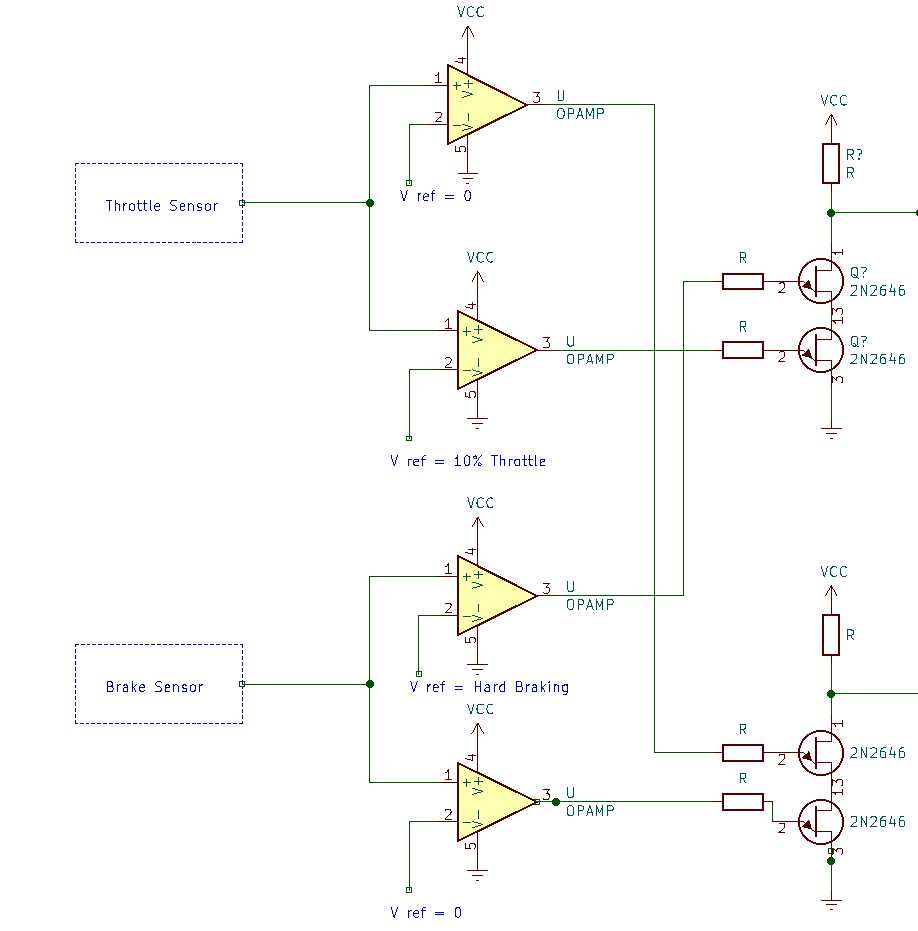

Electrical is focusing on several projects improve reliability and performance for our next car. With our new wireless hardware and software platforms for telemetry, we are able to view critical sensor data live and observe performance of the vehicle while driving. We transmit data from CAN and digital channels across a shared API allowing us to view telemetry across multiple clients simultaneously. Our new members have designed and simulated a new brake plausibility PCB which ensures safety of the vehicle under high throttle/brake conditions. Harness and formboard design is being modernized with version control and 2D schematics with 1:1 scale for more streamlined manufacturing.

Thank you again for your support. BFR hopes everyone is doing as well as possible with the current circumstances, and now more than ever appreciates the alumni, sponsors, and community who make this team what it is.

Want to receive the latest updates? Sign up for our mailing list!